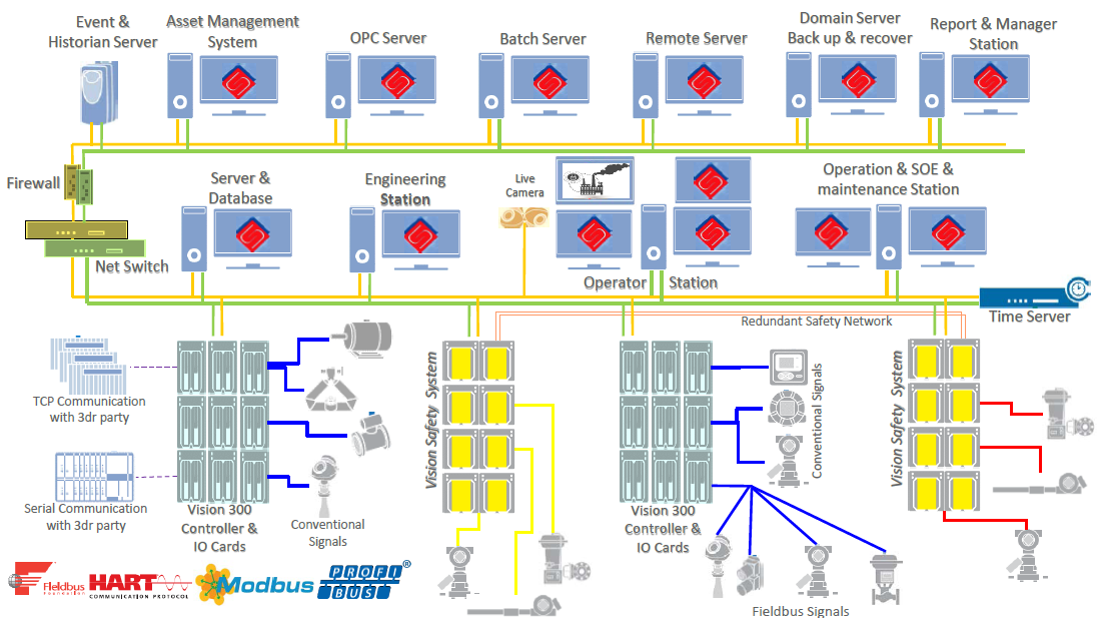

What is a V-PAS?

Vision Process Automation System (V-PAS) truly allows customers to integrate 4-20 mA signals, HART signals, Discrete signals, Foundation™️ Fieldbus signals, Serial Signals in the same controller and I/O architecture and has plant availability at a peak of performance that is the ultimate goal of any automation system. Vision process automation system keeps the facility running safely and securely while optimizing production. Conventional I/O is a modular subsystem that offers flexibility during installation. It is designed to be installed in the field with the devices. Modularity, protection keys, and plug-and-play capabilities make V-PAS I/O a smart choice for your process control system.

Vision Process Automation System ( V-PAS ) Architecture

Vision Process Automation System ( V-PAS ) Architecture

Vertical Design and Horizontal Design

The SubTek Control System is Designed in Two Versions

Vertical-Design

Vertical System (Backplane Base)

- Modern platform

- Easy online expansion

- Plug and play I/O

- Modular and flexible construction

- Field mounted capable hardware

- Integrated platform, DCS and SIS

- Secured Design

- Pre-fabrication and Traditional Termination

Vertical Design Benefits

- Combines I/O processor and field terminations in one assembly

- Preformed cable and field termination in one assembly

- Easy maintenance

- Effective Heat Exchange

Components

Horizontal

Horizontal System (Rack Base)

- Modern platform

- Easy online expansion

- Plug and play I/O

- Modular and flexible construction

- Field mounted capable hardware

- Integrated platform, DCS and SIS

- Secured Design

- Cost Effective

Horizontal Design Benefits

- Combines I/O processor and

field terminations in one assembly - Easy maintenance

- Effective Hardware Space

- High Installation Speed