Main Automation Contractor (MAC):

The Main Automation Contractor (MAC) provides project management , the supply of expertise, products, systems and services. It also provides interface management of the engineering suppliers to ensure common supply and takes responsibility for the data transfer between parties. Initial concept design and Front-End Engineering & Design (FEED) studies can be undertaken to rationalize process requirements Leading to practical, optimal solutions.

MAC scope of supply:

SUBTEK has considerable experience in the MAC role for projects and can take total responsibility for the management of the automation/instrumentation, selection,

Manufacture, installation, commissioning and after-sales support. A project sponsor will form a direct point of contact with SUBTEK’s Executive Management. He will work within a steering committee consisting of senior members of the clients project team. By assigning SUBTEK as the MAC early in a project, SUBTEK will gather engineering requirements, optimize the scope definition and therefore reduce both CAPEX and OPEX Costs. This also reduces the project schedule, engineering required and change requests.

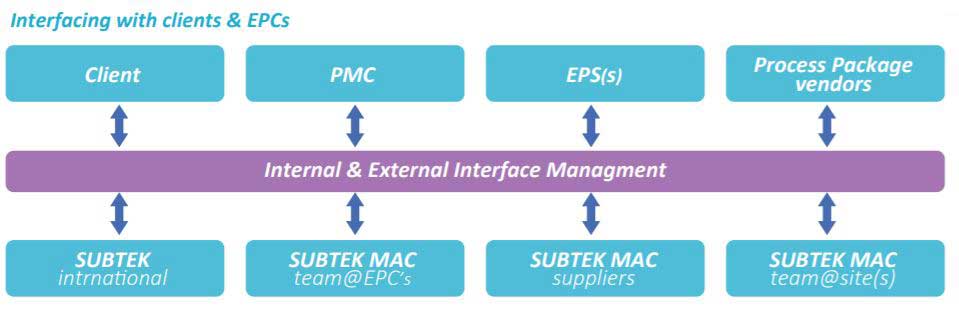

Where there are multiple contractors (EPCs) supplying the different process units, SUBTEK will perform the Interface management function to ensure a consistent, compatible solution. This eliminates the need for the Client or Project Management Contractor (PMC) to co- ordinate and pass information between many different parties.

Co-ordination and interface between major EPCs:

This ensures that the concepts and requirements developed during the FEED phase are implemented effectively and the design standardization is achieved across the facilities.

Wider scope than conventional vendors:

Focus is on working pro-actively with clients and PMCs to deliver the complete solution.

Product solution using MAC and third party suppliers:

The MAC takes integration responsibility for these products with the process and packaged plant equipment provided by the EPC(s). The MAC assists or undertakes the Installation of the completed system(s) under the direction of the EPC(s).

Final commissioning and start-up assistance:

Final commissioning and start-up assistance is achieved by working under the direction of the EPC(s) at the construction site(s).Thus the integrated automation system Is coordinated across the multiple process units.

Reduced risks:

Risks are reduced by aligning the different engineering teams involved and the products supplied to minimize surprises at all stages of the project. As all of the equipment is known to work together, risk is reduced during the project implementation and on site. SUBTEK’s device integration testing reduces reliance on individual suppliers’ statements on compliance to standards.

Main Automation Contractor (MAC):

A Main Automation Contractor (MAC) provides project management , the supply of expertise, products, systems and services. It also provides interface management of the engineering suppliers to ensure common supply and takes responsibility for the data transfer between parties. Initial concept design and Front-End Engineering and Design (FEED) studies can be undertaken to rationalize process requirements Leading to practical, optimal solutions.

MAC scope of supply:

SUBTEK has considerable experience in the MAC role for projects and can take total responsibility for the management of the automation/instrumentation, selection,

manufacture, installation, commissioning and after-sales support. A project sponsor will form a direct point of contact with SUBTEK’s Executive Management. He will work within a steering committee consisting of senior members of the clients project team. By assigning SUBTEK as the MAC early in a project, SUBTEK will gather engineering requirements, optimize the scope definition and therefore reduce both CAPEX and OPEX Costs. This also reduces the project schedule, engineering required and change requests.

Where there are multiple contractors (EPCs) supplying the different process units, SUBTEK will perform the Interface management function to ensure a consistent, compatible solution. This eliminates the need for the Client or Project Management Contractor (PMC) to co- ordinate and pass information between many different parties.

Co-ordination and interface be tween major EPCs:

This ensures that the concepts and requirements developed during the FEED phase are implemented effectively and the design standardization is achieved across the facilities.

Wider scope than conventional vendors:

Focus is on working proactively with clients and PMCs to deliver the complete solution.

Product solution using MAC and third party suppliers:

The MAC takes integration responsibility for these products with the process and packaged plant equipment provided by The EPC(s). The MAC assists or undertakes the Installation of the completed system(s) under the direction of the EPC(s).

Final commissioning and start-up assistance:

Final commissioning and start-up assistance is achieved by working under the direction of the EPC(s) at the construction site(s).Thus the integrated automation system Is coordinated across the multiple process units.

Reduced risks:

Risks are reduced by aligning the different engineering teams involved and the products supplied to minimize surprises at all stages of the project. As all of the equipment is known to work together, risk is reduced during the project implementation and on site. SUBTEK’s device integration testing reduces reliance on individual suppliers’ statements on compliance to standards.

Typically, these projects involve multiple EPCs and process package vendors. Therefore, in addition to the normal project issues, they require the co-ordination of the EPCs to achieve a common, compatible design for the overall system that meets the requirements of the process plant application. In order to manage and control these multiple requirements, common functional design specifications (CFDS) for each system (distributed control system (DCS), safety instrumented system (SIS),power management system (PMS),telecoms system etc.) will be developed and agreed as appropriate with the client’s management team at an early stage in the project. This CFDS defines the design requirements of the systems and details aspects of the designs that must be common for each project section. SUBTEK will then take these CFDS and develop compliant specific system design specification for each EPC. This ensures that commonality exists across the design and that the final project integrates seamlessly. As part of the CFDS preparation, SUBTEK will identify the use of Its system libraries and standard designs/solutions for the particular industry or application, so reducing risk and cost.

Typically, these projects involve multiple EPCs and process package vendors. Therefore, in addition to the normal project issues, they require the co-ordination of the EPCs to achieve a common, compatible design for the overall system that meets the requirements of the process plant application. In order to manage and control these multiple requirements, common functional design specifications (CFDS) for each system (distributed control system (DCS), safety instrumented system (SIS), power management system (PMS), telecoms system etc.) will be developed and agreed as appropriate with the client’s management team at an early stage in the project. This CFDS defines the design requirements of the systems and details aspects of the designs that must be common for each project section. SUBTEK will then take these CFDS and develop compliant specific system design specification for each EPC. This ensures that commonality exists across the design and that the final project integrates seamlessly. As part of the CFDS preparation, SUBTEK will identify the use of Its system libraries and standard designs/solutions for the particular industry or application, so reducing risk and cost.